Blog

Transforming industry: Why it’s time to switch from steam to renewable heat

10 November 2025

Blog

10 November 2025

Steam-based heating systems, typically powered by fossil fuels, are still widely used in factories around the world. Historically effective, they now come with significant downsides: high greenhouse gas emissions, energy loss and rising operational costs.

As industries face growing pressure to decarbonize, Renewable Thermal Systems (RTS) like heat pumps, hot water systems and thermal energy storage offer a practical, cost-effective solution to make industrial processes cleaner and more efficient.

With over 20 years of experience in industrial energy efficiency, ATIS Énergie is leading the way in this transition, helping manufacturers reduce emissions while improving process performance.

Renewable Thermal Systems (RTS): Cleaner, smarter heat

1. High-temperature industrial heat pumps

Industrial heat pumps transfer heat from a source (air, water, ground or waste heat) into industrial processes. Thanks to technological advances, many modern pumps can now reach temperatures above 160°C, making them a viable alternative to stream in many industrial applications.

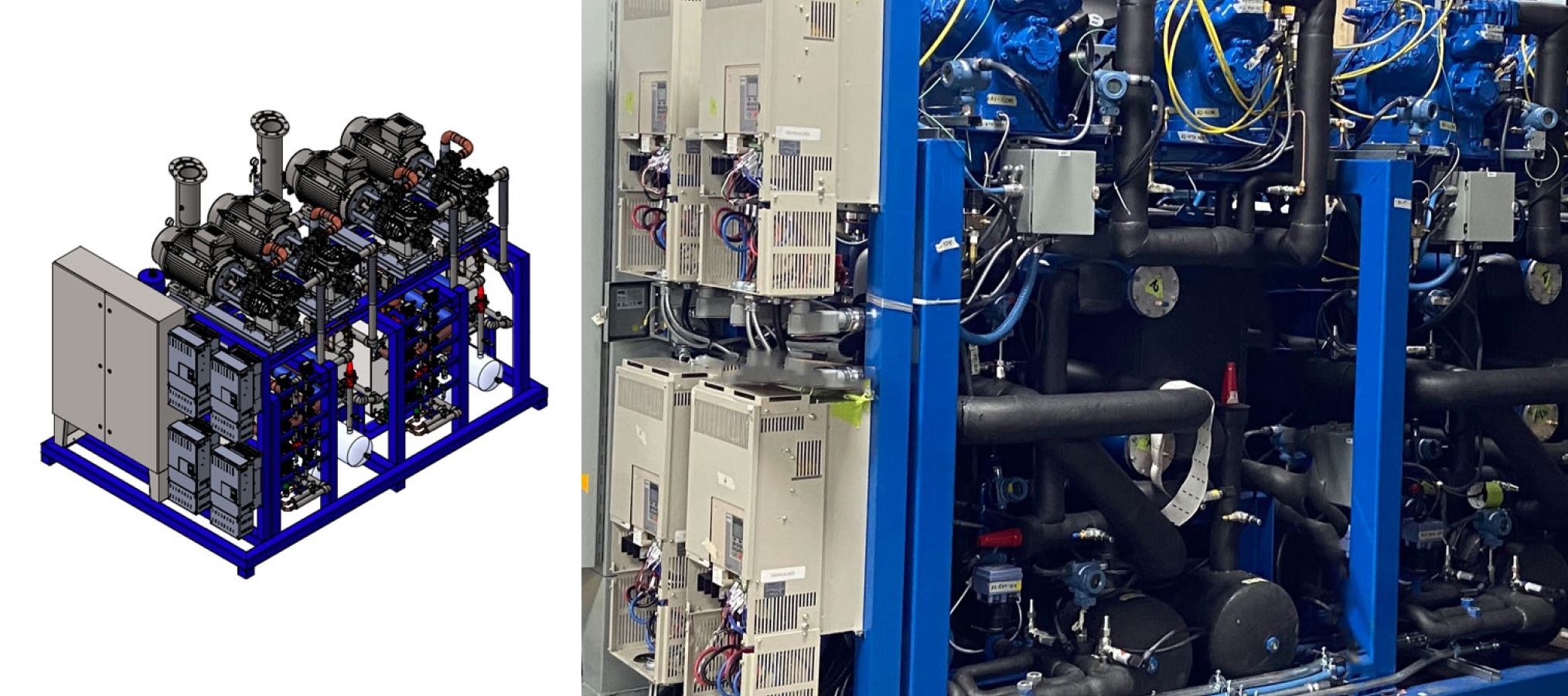

At ATIS Énergie, we design and deploy industrial-grade, high-temperature heat pumps, tailored to meet the rigorous demands of industrial clients looking to move away from steam. Built in collaboration with Canadian manufacturers, these solutions are engineered for durability, energy efficiency and compatibility with complex industrial environments.

2. Hot water systems

For processes under 100°C, hot water systems are a safer and more efficient alternative to steam. They offer precise energy control and can integrate easily with renewable energy sources.

3. Thermal Energy Storage (TES)

TES systems store heat produced via heat pumps or solar thermal for later use. This helps optimize energy management and improves the flexibility and resilience of industrial processes.

Policy drivers supporting RTS adoption

Government and industry policies are increasingly creating favourable conditions to accelerate the adoption of renewable thermal systems:

Carbon pricing: Makes fossil-fuel systems less competitive.

Subsidies and tax credits: Programs such as Canada’s Clean Technology Investment Tax Credit and Quebec’s ÉcoPerformance help offset capital costs.

Efficiency mandates: Encourage modernization of thermal systems.

R&D funding: Supports innovation of high-temperature heat pump technologies.

Utility programs: Promote electrification and demand-side management.

Challenges and how to overcome them

Despite their promise, switching to RTS comes with challenges:

High upfront investment: Heat pumps and TES systems require significant capital.

Integration with existing processes: Not all facilities can easily switch from steam.

Technical expertise: Proper integration demands specialized engineering.

Grid capacity: Electrification increases local electricity demand.

Risk aversion: Industries may hesitate without clear proof of ROI.

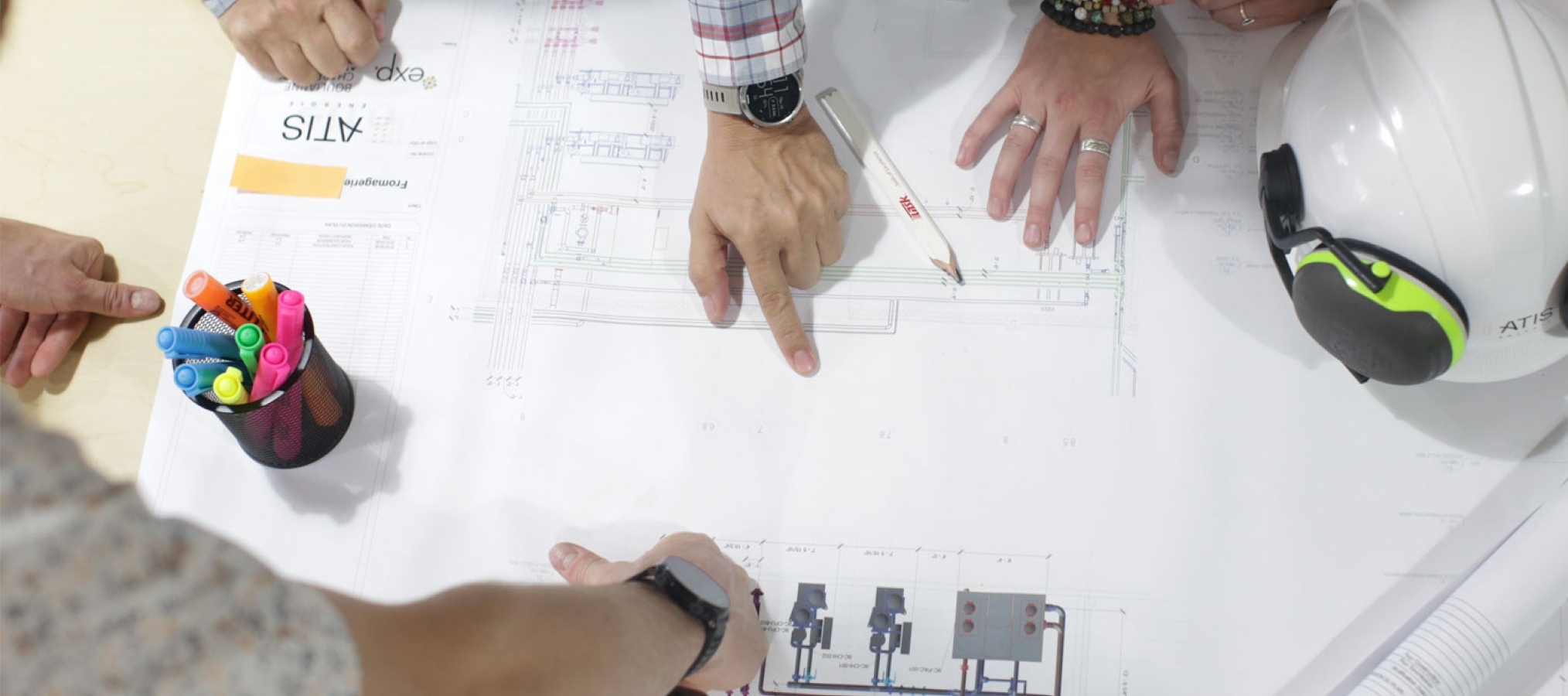

ATIS Énergie helps clients navigate these hurdles by offering custom feasibility studies, thermal simulations and pilot projects. Our deep experience ensures that RTS solutions are not only technically sound but also financially viable.

Financial and organizational support

Industries can leverage various support mechanisms to make RTS adoption easier:

Government grants and rebates: Available for feasibility studies and installations.

Green financing: ESG-linked loans and bonds support clean energy investments.

ESCO partnerships: Energy Service Companies can finance, install and operate RTS under performance-based contracts, reducing upfront costs for the industrial client.

Collaborative networks: Organizations like the ASHRAE and others offer technical guidance and peer learning.

The benefits of switching to RTS

Lower emissions: RTS can reduce GHG emissions by up to 80% compared to fossil-fuel steam systems.

Improved energy efficiency: Heat pumps often achieve COPs (Coefficient of Performance) of 3 to 5, delivering 3–5 times more energy than they consume.

Cost savings: Lower operating costs, reduced maintenance and improved energy management add up to long-term savings.

Process optimization: More precise temperature control and seamless integration with digital systems help improve product quality and ensure consistent output.

Resilience and flexibility: RTS systems can integrate with on-site renewables, respond to dynamic energy pricing and reduce exposure to volatile fuel markets.

Act now to lead the shift in industrial heating

Transitioning from steam-based systems to RTS isn’t just a technical upgrade—it’s a strategic shift. As climate regulations tighten and energy markets evolve, industries that embrace renewable thermal solutions will be better positioned to thrive.

With our proven expertise and custom-designed high-temperature heat pumps, ATIS Énergie is a trusted partner in this transformation. By leveraging locally manufactured technologies and deep industrial know-how, we support clients in moving toward cleaner, more efficient and more reliable thermal energy, without compromising performance.

The future of industrial heat is renewable, and the time to act is now. Contact us!

24 February 2026

The 12th edition of The State of Energy in Québec, published by HEC Montréal, sends a clear message to Québec’s industrial sector: the energy environment is changing quickly, and strategic planning can no longer rely on past assumptions.

3 April 2024

ATIS Énergie is celebrating 20 years at the forefront of the fight against climate change. To mark this anniversary, we're taking a look at how the field has changed over the past two decades. We believe that protecting the environment through energy management is more important than ever—for us and for future generations.

20 May 2025

Quebec is sitting on an energy source that’s all too often overlooked: waste heat emissions. Generated primarily from industrial processes, wastewater treatment plants, data centres and incinerators, this thermal waste is a significant source of energy that can—and should—be recovered and reused. Let’s look at how waste heat can be repurposed to meet the energy needs of buildings and industrial operations.