Quadrupling chemical production

Context

Since 2008, ATIS Énergie has been supporting a major chemical producer in its mission to reduce energy consumption at its main site in Quebec. The company’s vast industrial complex is made up of more than 150 buildings.

Our accomplishments

Comprehensive audit of the site performed in 2008

Designed and implemented Engineering, Procurement and Construction Management (EPCM) projects for an integrated energy recovery, management and distribution system in the plant’s most energy-intensive sector

Designed energy recovery systems for distillation columns

Designed and implemented (EPCM) an energy recovery network

Designed and implemented (EPCM) renewable thermal energy production systems

Designed and implemented (EPCM) energy supply and production systems for new buildings on the industrial site

Results

This project, carried out in 2016, involved implementing integrated networks for the recovery, distribution, accumulation and recovery of thermal energy from renewable sources

Deployed a heat network spanning several kilometres

Installed infrastructure to produce renewable thermal energy

Annual reduction in energy consumption equivalent to 9 GWh in electricity and 200,000m³ of natural gas

This producer has expanded its operations in recent years, significantly increasing its production capacity while developing several new products. This growth has resulted in the addition of several dozen new buildings on the site. We were tasked to oversee all industrial processes and energy management for the entire project, to take care of all industrial processes and energy management for the entire project, covering both existing and new buildings.

Our accomplishments

Full site energy audit performed in 2016

Designed and implemented (ECPM) energy-efficient systems for new buildings

Implemented heat recovery systems from exothermic processes, allowing both old and new buildings to be heated, in addition to supplying existing and future exothermic processes

Designed a cooling network for air conditioning new buildings;

Designed and implemented (EPCM) integrated energy systems for all site buildings, both old and new

Designed and implemented (EPCM) several dozen kilometres of heating and air conditioning networks

Results

Our energy management strategy, focused on efficiency and innovation, proved to be cost-effective for our client

We implemented an additional power block of less than 5 MW significantly less than conventional demand requiring close to 30 MW

Energy savings of up to 50 GWh per year, representing a reduction in operating costs of more than $8 million annually

Efficient energy use meant we could avoid using natural gas, thus avoiding the equivalent of up to 9,000 of CO₂ emissions per year

Implemented several tens of kilometres of thermal and air conditioning networks

Deployed exothermic process energy recovery infrastructures, allowing this energy to be redistributed to new and existing heat-consuming buildings and processes

32% reduction in steam production at a pulp & paper mill

Context

Concerned about its energy performance, a pulp & paper mill called on our expertise to identify savings opportunities to bolster its in-house efforts.

Over the years, ATIS Énergie has carried out various opportunity studies at different plants within the company. Each one has revealed significant potential for reducing energy consumption along with greenhouse gas emissions.

One of the studies, carried out at a containerboard plant, showed particularly promising potential. We proposed a solution that involves rethinking the plant’s energy infrastructure to reduce the use of steam by replacing it with hot water, where possible. This approach allows for a more efficient use of thermal energy.

This project will allow the plant to increase its production capacity while maintaining its existing steam production and distribution infrastructure, leading to long-term energy efficiency gains.

Main actions to be implemented

- Reduce steam production in boilers with a series of targeted measures

- Recover heat from evaporator condensers and water tower

- Construction of new facilities to accommodate the majority of equipment required, due to lack of space in existing plant

- Improve the paper machine’s operational flexibility

- Optimize steam shower feed

Expected results

Reduction of 48,000 lb/h (32%) in steam production at the pulp & paper mill, generating annual savings of close to $6 million

Possibility of operating solely on biomass for steam production, with the electric boiler as a backup in the event of a wood-fired boiler breakdown

Both oil-fired boilers can be shut down, eliminating fuel oil consumption

Reduce GHG emissions by 12,000 tCO2e

Annual steam production savings of $7.5 million, resulting in a return on investment in less than 3 years

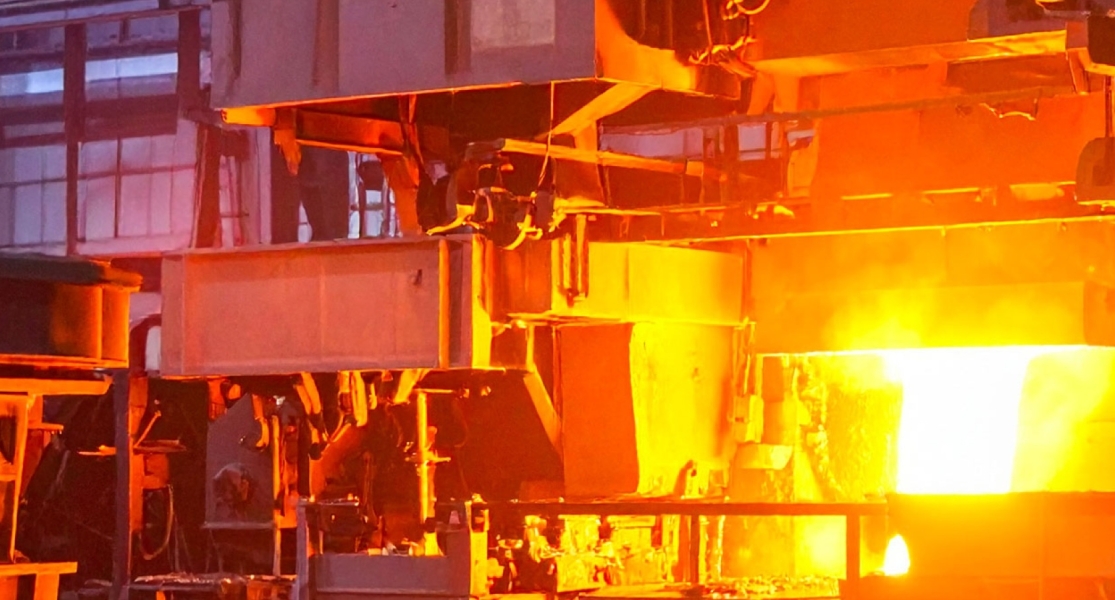

Recovering excess heat from a 50 MW foundry furnace

Context

A foundry identified a high-potential opportunity to generate new revenue by recovering excess heat from its 50 MW industrial furnace. This project involves recovering the furnace’s cooling water at approximately 65°C and converting this heat into superheated steam at a minimum pressure of 12 barg (Tsat 192°C). The goal is to supply the thermal processes at an adjacent plant via a steam network spanning several kilometres.

Our accomplishments

Increase cooling water temperature to 62–65°C and extract heat efficiently

Generate vacuum steam followed by mechanical recompression to 9 barg

Use motive steam from the existing boiler to increase steam pressure to 13–14 barg

Install a 12-inch steam line on the existing route connecting the two plants

Expected results

Approx. 21,000 kg/h of steam produced from the recovery of heat from the cooling water of the furnace

Nearly 5 MW of power used for this production through mechanical recompression

Supply of an additional 15 MW of heat to the client’s plant

Reduction in greenhouse gas emissions estimated up to 25 000 tCO₂e per year