Les Viandes duBreton, Rivière-du-Loup

Context

In an effort to significantly reduce its energy consumption and carbon footprint, duBreton retained ATIS to propose and implement important measures that would help the company achieve its objectives.

The first phase, carried out in 2012, consisted of installing a renewable thermal energy production system using high-temperature heat pumps, amongst other things. The project was largely fuelled by waste heat from cooling systems that recover up to 5 MW of thermal energy. High-temperature heat pumps produce more than 2 MW of energy at > 80°C. The project has completely eliminated fuel oil consumption (more than 1 million litres per year).

The second phase, completed in 2015, significantly reduced the consumption of propane for heating fresh air. Atis Énergie is currently implementing the third phase (2023) of this ambitious energy transition program, which will reduce electrical energy consumption by more than 5 MWh/year in addition to minimizing the use of propane.

Our accomplishments

- Energy audit

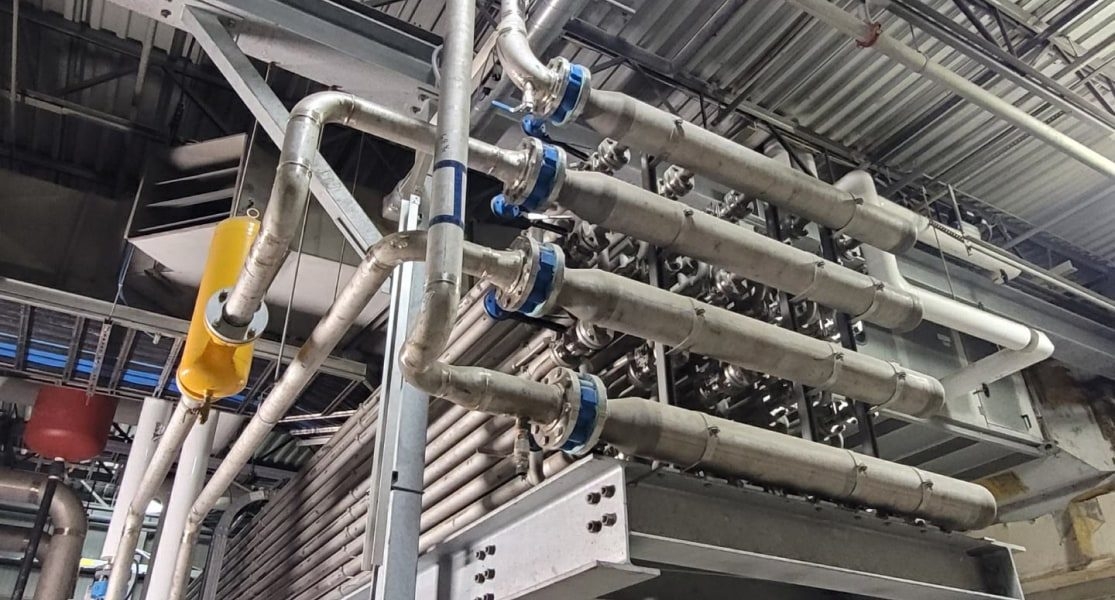

- Design and supply of projects for the upgrading, production and distribution of renewable thermal energy for hot water production, fresh air heating systems and dehumidification, including:

- Design and integration of energy recovery systems for cold generation [alt: production] compressors

- Design and supply of effluent energy recovery systems

- Design, supply and installation of a pig hair burner waste heat recovery system.

- Design, supply and installation of an energy management system for an hydraulics system equipped with waste heat recovery system,

- Design and supply of high temperature (3 MW) heat pumps

- Design, supply and installation of fresh air heating system (120,000 CFM)

Olymel

Context

With more than thirty processing plants, Olymel is the largest meat producer and processor in Canada. The company want to improve their energy productivity. Olymel called on the expertise of ATIS Énergie to improve its environmental performance while reducing its energy consumption and GHG emissions. Atis Énergie has been supporting Olymel since 2017, and to-date has carried out projects in 3 plants: Saint-Esprit, Yamachiche and Sainte-Rosalie.

Our Accomplishments

Turnkey projects, including engineering, procurement and construction management

- Design, supply and installation of a thermal energy recovery system for cooling systems condensers (10-15 MW per plant)

- Design, supply and installation of a thermal energy recovery system for plant effluents

- Design, supply and installation of a renewable thermal energy production system using a 2 MW heat pump

- Design and supply of high-quality thermal energy recovery systems for pig hair burners

- Design, supply and installation of a system for the production and distribution through heat distribution network of thermal energy, as well as a domestic hot water production system

- Design, supply and installation of a thermal energy production and heat distribution network system for a fresh air supply system (80,000-120,000 CFM per plant)

- Design and implementation of an Energy Management Information System (EMIS) for collecting and archiving operational data on energy production by process and production unit

Results

- Up to 80% reduction in GHG emissions

- Over 30% reduction in total energy consumption

- Increased capacity of the condensing systems of the plant's main coolers

- Implementation of thermal energy recovery and production networks with sufficient capacity to satisfy present and future energy requirements

- Design and installation of energy recovery systems for pig hair burners and effluents integrated into the heat distribution network

- Design and installation of energy distribution network to supply energy to fresh air units (80,000 CFM to 120,000 CFM)

- Design and implementation of systems for the production and storage of renewable thermal energy from energy recovery

- Thermal energy consumption and production monitoring system to monitor and detect specific energy trends and deviations

International dairy processing company

Context

A high-profile international agri-food company committed to significantly improving the energy efficiency of its production sites and reducing its greenhouse gas emissions by 2030.

We worked with them to develop a project aligned with their vision—and went even further. The results far exceeded the company’s targets and became its global benchmark for energy savings.

Our accomplishments

In-depth analysis of energy saving potential

Full project management using an ECPM (Engineering, Procurement, Management and Construction) approach;

Gathering required certifications

Identifying and obtaining available subsidies

Implementation of an Energy Management System (EnMS), an Energy Management Information System (EMIS), and support toward ISO 50001 certification

The results

Reduction of more than 5.000 tonnes of GHG emissions per year, representing a significant proportion of total emissions in 2023

More than 30% reduction in energy consumption in 2024 compared to 2023, generating annual savings of over $1 million

ISO 50001 certification - the global standard for energy performance recognition

Le Groupe Bel

Context

For the construction of its new cheese production plant in Quebec, Bel Group called on ATIS Énergie to design and implement an innovative thermal energy production system based on resource sharing between 2 plants. The mandate: a concept for the implementation of the plant’s building mechanics and for the integration of a system for the management and production of thermal energy between 2 plants.

Our accomplishments

Energy Audit (2017)

Detailed engineering for building and process mechanics for the construction of the first Babybel production plant in Canada

Project for the design and supply of the modular system for the production and distribution of thermal energy

Design and programming of the control system for the production and monitoring of the plant's thermal energy production

Design, supply and programming of a dynamic ventilation control system to ensure air pressure conditions are maintained between production rooms, according to different production modes

Energy audit of a Bel plant in Portugal

Installation of systems for the recovery of cold and milk, and for preheating pasteurization

85 to 90% reduction in GHG emissions, i.e., more than 1,500 tons of CO2 equivalent

Reduction of the heating and cooling production capacity required by the shared services between two plants (Bel and Riviera)

Real-time automatic balancing of ventilation airflows to maintain relative pressures between different production rooms

Heating of ventilation systems (production and offices), more than 95% of the time with direct heat recovery from refrigeration systems and production processes

Coop Agrilait, Fromagerie St-Guillaume

Context

Fromagerie St-Guillaume, Atis Énergie’s first “cheese” client, wanted to integrate new energy services into the plant’s mechanics during a plant expansion that included the addition of new administrative offices. The cheese producer has made important changes in its energy management, resulting in significant energy savings.

Our Accomplishments

- Implementation of projects to reduce the energy consumption of the whey drying system by more than 60%

- Improved energy efficiency of 2-effect evaporator and whey drying system

- Design and supply of ventilation system for new administrative buildings and plant

- Energy recovery and management (including a centralized cooling system)

- Design and supply of ripening rooms

- Increased capacity of the plant’s cooling system

Results

- Increased drying capacity of whey drying system

- More than 65% reduction in GHG emissions

- Transformation of fridge operation for glycol operation

- Use of heat pump for independent controlled environment control by administrative office area

- Implementation of significantly more efficient milk pasteurizers

- Installation of thermal batteries